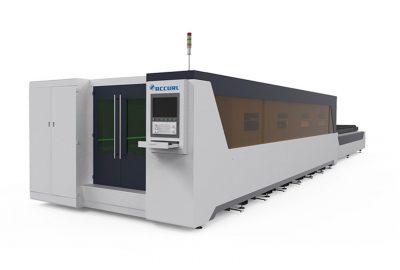

دستگاه برش لیزری ACCURL ECO-FIBER KJG

سری اکو فیبر لیزر Accurl Fiber با قابلیت برش سریع و قابلیت بهره وری در مصرف انرژی در مقایسه با CO2 با استفاده از فناوری آسان فیبر لیزر ، استفاده آسان ، تعمیر و نگهداری به دست آمده است. شرکت شما.

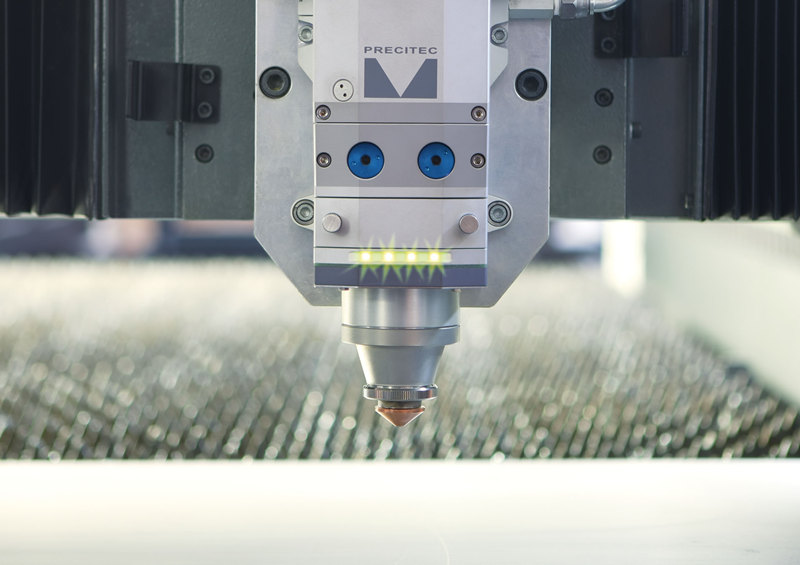

Cutting Head

√ The Laser beam is delivered to the cutting head by fiber optic cable.•The fiber optic cable is fixed to the input of cutting head.

√ The laser is delivered to the focusing unit after being aligned in the collimator. The laser beam is set to desired focus using the lenses in the focusing unit.

√ The protection glass protects the lenses from the particles which are caused by the cutting operation.

√ The sensor insert is part of the elevation control system and helps to adjust the distance between material and cutting head.

√ Elevation control is checked with the most precise sensors in the market. This helps to produce better cuts.

√ The main function of the ceramic is to protect the cutting head.

√ The nozzle is used to control the assist gases. It is also a part of the capacitive control system.

Control&Software

The ACCURL Fiber Laser is controlled with a Beckhoff CNC control unit which provides unprecedentde control of the cutting process. The control panel features an alphanumeric keyboard, PLC keys on the sides, touch screen keyboard and USB ports. The memory and storage can be increased based on manufacturing demands while the open CNC program, with a Windows based operating system, makes data sharing easy with other computers. A 15 TFT LCD screen ensures that even in poor lighting you have optimal address ability and contrast.

High Precision Drive Systemcutting Table

The dual cutting table system is designed for in creasing your work flow and reducing time spent on placing and removing materials. Four hydraulic cylinders raise and lower the cutting table to position the material while loading and unloading the machine.Cutting table exchange speed can be adjusted according to thickness of materials.

Conveyor System

A special hard steel construction conveyor system,standard on our machines, is located under the workspace. The conveyor removes slag and small parts during the cutting process. The operator can choose. the movement direction of the conveyor.